Custom Casting/Forging/Machining Steel/Iron/Metal Parts for Forklift/Tractor/Trailer/Dumper/Self-Dumping/Discharging Truck

Basic Info.

| Material | Custom Drawings OEM |

| standard | ISO ,GB, DIN, AISI, ASTM, BS, JIS, etc. |

| Size | available in all sizes or as customer's drawings |

| Certification | ISO9001 2015 |

| Application | Industrial parts,Machinery parts, Mechanical parts, construction parts, Marine Hardware, valve parts, Electric power fittings, Pipe Fittings, Metal parts, Auto parts, train, craft, Industrial parts, hydraulic pressure, agricultural machinery, Marine hardware, Auto parts, electric power fittings, food machinery, harness fittings, tools, mining machinery parts, Hinges, etc |

| Weight range | 0.01kg-3000kg |

| Machining precision | ±0.01mm |

| CNC and MC Machining | Three coordinate measurement machine for testing. |

| Service | To chart to sample production OEM / ODM |

| MOQ | Small order is accepted |

| Remark | Making service as per your requirement or drawings |

Manufacture Process

1. Review the part design,drawings and quality standard from clients.

2. Mould and Tooling design & manufacturing

3. Mould and Tooling testing & confirm the sample

4. Die casting raw castings

5. Surface treatment: Trimming,Deburring, polishing, cleaning, passivation & power coating and other requirement from Customer

6. Precision machining: CNC lathes, milling, drilling, grinding etc

7. Full Inspection

8. Packaging

9. Delivery

Aluminum Die Casting

In the pressure Aluminum Die Casting process the metal is forced into a high grade steel tool at high speed and pressure. The casting temperature is roughly 700°C when you do Aluminum Die Casting, 650°C when you do Magnesium Die Casting, 1000 °C when you do Brass Die Casting. The use of vacuum Aluminum Die Casting technique is a must in order to achieve superior quality for extremely light and thin walled components.

Aluminum Die Casting is a competitive casting method when the Aluminum Die Casting components are needed at high volumes or when better tolerances and surface finish are required than can be achieved by gravity aluminum die casting. The need for Aluminum Die Casting Products machining is very low due to the close casting tolerances. Heat treatment of pressure Aluminum Die Casting Products is possible, due to the high rate of solidification the mechanical properties are good. The Aluminum Die Casting tooling costs are considerably higher than for gravity die casting.

Investment casting

Lost-wax casting (also called "investment casting", "precision casting", or cire perdue which has been adopted into English from the French) is the process by which a duplicate metal sculpture (often silver, gold, brass or bronze) is cast from an original sculpture. Intricate works can be achieved by this method.

The oldest known example of this technique is a 6,000-year old amulet from Indus Valley Civilization. Other examples from somewhat later periods are from Mesopotamia in the third millennium B.C. and the objects discovered in the Cave of the Treasure (Nahal Mishmar) hoard in southern Palestine (region), and which belong to the Chalcolithic period (4500-3500 BC). Conservative estimates of age from carbon-14 dating date the items to c. 3700 BC, making them more than 5,700 years old. Lost-wax casting was widespread in Europe until the 18th century, when a piece-moulding process came to predominate.

The steps used in casting small bronze sculptures are fairly standardized, though the process today varies from foundry to foundry. (In modern industrial use, the process is called investment casting.) Variations of the process include: "lost mould", which recognizes that materials other than wax can be used (such as: tallow, resin, tar, and textile); and "waste wax process" (or "waste mould casting"), because the mould is destroyed to remove the cast item.

Our wax casting product processed by 79 steps with high standard and 100% inspection. Along with the power of our advanced machine, quality is something you do not need to worry about.

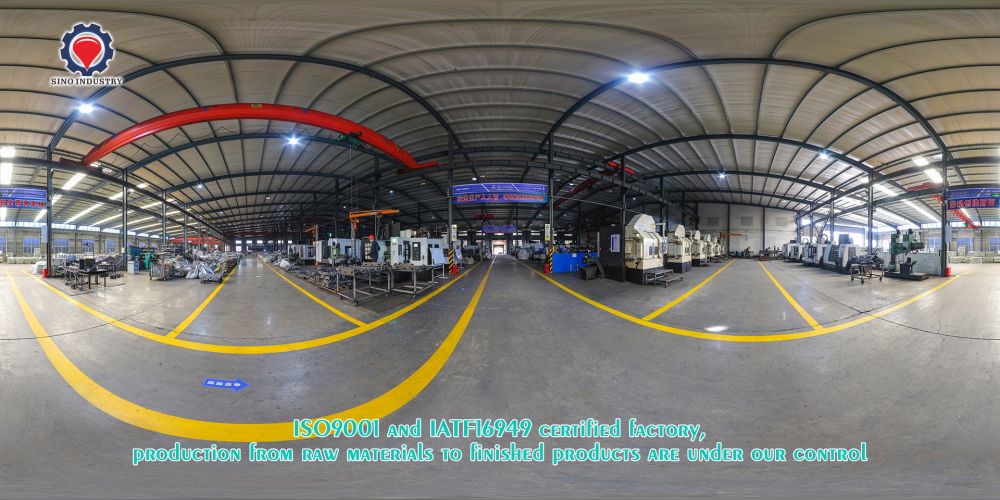

Sino Industry and Trade Company is a high-tech enterprise combines designing, tooling developing, casting, machining, surface treatment, inspection, sales and service all together. The company wholly owns a subsidiary production factory named “Rizhao Longshan Pricision Machinery Manufacture Co., Ltd.”, which possesses superior production equipment, strict and effective quality assurance system, excellent and perfect detection means, rich and abundant technical force. Founded in 1980, located in Rizhao City, Shandong Province, P.R. China, the factory cover an area of more than 600,000 square meters.

With a massive research & development environment, JY utilized market-leading technology and introduced various of advanced equipment to ensure the stringent quality in production.

Under a powerful management team, the company has growing to the group with more than 800 employees. Products range includes casing parts, forging parts, machining parts, and so one.

FAQ

Q: What do I need for offering a quote?

A: Please offer us 2D or 3D drawings (with material, dimension, tolerance, surface treatment and another technical requirement, etc.), quantity, application, or samples. Then we will quote the best price within 24h.

Q: What is your MOQ?

A: MOQ depends on our client's needs, besides, we welcome trial orders before mass production.

Q: What is the production cycle?

A: It varies a lot depending on product dimension, technical requirements, and quantity. We always try to meet customers' requirements by adjusting our workshop schedule.

Q: What kind of payment terms do you accept?

A.: T/T, L/C, PayPal.

Q: Is it possible to know how is my product going on without visiting your company?

A: We will offer a detailed production schedule and send weekly reports with digital pictures and videos which show the casting and machining progress.

Q: What is the packaging?

We promise our clients careful, safe and tight package for exporting! Standard packing: pearl cotton/bubble bag + carton box + pallet/wooden box. Special packing: custom packaging + wooden case.